SISTER2 is now available for hire!

Updated version of SISTER (2021), BRI’s mobile air quality laboratory.

SISTER2 is an air quality laboratory in a 1-ton box, available for advanced gas leak detection and assessment. SISTER2 deploys by a pickup truck, boat, or trailer and measures 14 gases, aerosols, and meteorology at up to highway speed. SISTER2 can support natural gas companies, the oil and gas industry, government, and research collaborations to protect our communities and the environment.

There is a growing need for approaches to derive trace gas emissions from various natural and anthropogenic sources to validate emission factors for real-world conditions where systems may be less than ideal. One approach that technological innovations have led to growing applications is mobile vehicle-based air-quality laboratories designed to collect data during surveys. Mobile air-quality labs can collect data in the wind and plume frame of reference and are amenable to adaptive surveys wherein real-time data is used to adapt the survey strategy to improve science outcomes.

The road to SISTER2…

BRI has conducted mobile air quality laboratory surveys since 2014. These surveys have been to estimate emissions from a variety of sources including oil & gas, husbandry, landfill, natural seepage, pipeline leakage, and volcanic, and to assess air quality in diverse communities, as well as to validate airborne and satellite data. The first BRI development was AMOG Surveyor™, an air quality measurement laboratory in a Nissan Versa that measured 12 different trace gases at ppt to ppb levels. AMOG Surveyor was employed in numerous studies, from husbandry emissions to gas pipeline leaks (see full list of AMOG publications below*).

AMOG has since been retired to allow Standard Instrumentation Suite: Truck Enabled for Response: SISTER™ to take its place as the BRI air quality survey workhorse. SISTER now allows for off-road surveys and comprises a more complete (and heavier) payload than feasible for AMOG Surveyor. Underlying this generational change was a breakthrough in how to measure winds from a moving pickup truck.SISTER has been in use by BRI for the last 2 years and has conducted many studies of seep emissions, oil and gas emissions, and dairy emissions, including the recent BRI’s 2020 investigation of air quality at the Ports of Long Beach and Los Angeles during and after the Covid shutdowns.

SISTER evolution. Pre-SISTER towing AMOG. Proto-SISTER during an anemometer test – hence the two anemometers, SISTER 1 at the Port of Los Angeles, SISTER 2 returning from a survey at the Ports).

At the start of 2021 BRI updated SISTER to SISTER 2 in order to update performance and add additional measurements; thus, SISTER 2 has become the latest iteration of BRI’s mobile air quality laboratory. A notable feature of all SISTER models is BRI’s custom software that provides real-time GoogleEarth visualization of trace gases and winds to facilitate adaptive surveying which modifies survey plans to improve data quality.

SISTER2 Specs

A) and B) SIS-1 on TMOG in the Santa Ynez Mtns. above Santa Barbara on 4 June 2021. C) and D) SIS-2 on TMOG-2 on the Santa Ynez Mtn. ridge.

Analyzers

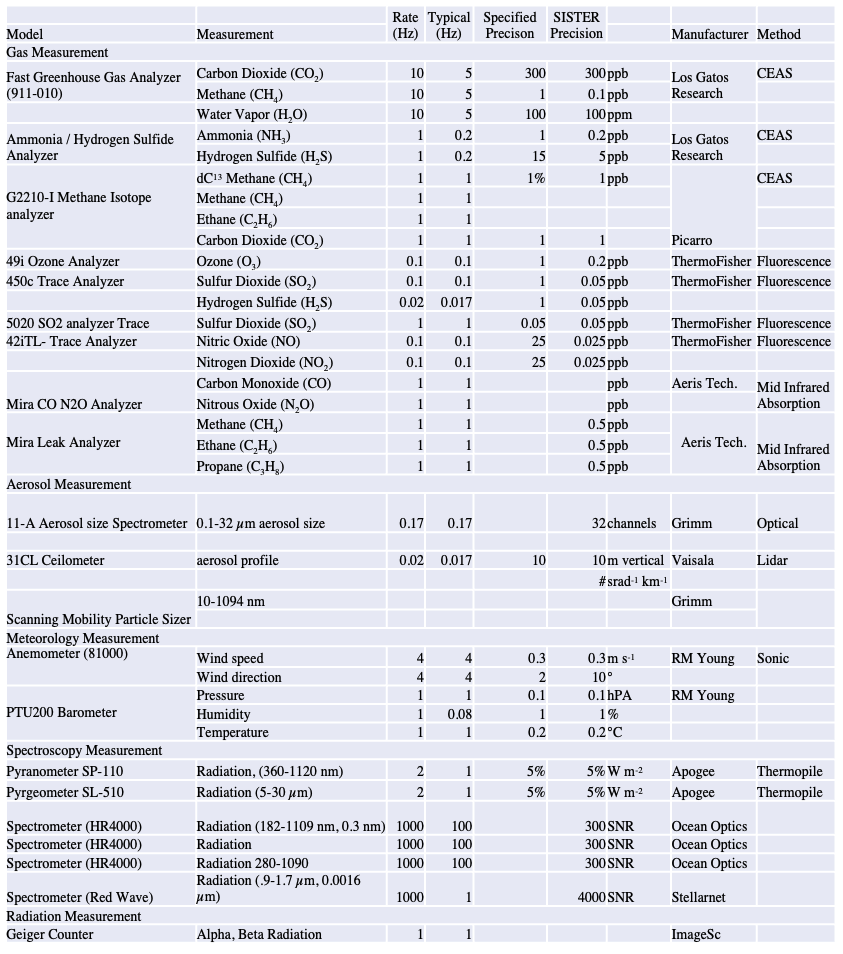

SIS measures 15 gases, meteorology (3D winds, temperature, pressure, humidity), aerosol profiles, and aerosol size spectra (0.1-32 µm, 32 channels, 0.16 Hz), solar insolation and spectra, and radiation. SISTER gases analyzed are d13CH4, CH4, C2H6, C3H8, CO2, CO, H2O, NH3, O3, SO2, NOX, NO, NO2, N2O, and H2S) at sub-ppb levels and CO2 and H2O at sub-ppm levels; see below table for instrumentation details. SIS includes targeted air sample collection in 48 evacuated canisters.

Pumps

A large external pump (XDS35i, Edwards, UK), the main pump, provides airflow for the FGGA and 42iTL analyzers. The addition of a bypass flow created by the main pump improves the time response of the FGGA, G2210i, 450c, and 5020 analyzers. The G2210i uses an external pump; the 450c and 5020 use internal pumps. Vacuum lines use a combination of stainless-steel Swagelok and NW25 vacuum fittings, with the main vacuum lines being NW25. Where feasible, welded stainless (Swagelok) fittings reduce the potential for leaks. Analyzer bulkhead fittings for sticky gases, such as SO2, were replaced with ¼” Teflon Swagelok and Swagelok-compatible fittings (Plasmatech, CA). Vacuum pumps and air compressors (for sample canisters or the ZAG generator) are in a thermally insulated and isolated pump compartment. The pump compartment has exhaust and intake fans.

A ¼” PFA pump line brings air into SIS from the same inlet point as the sample lines and then continuously flushes a fill line that flows through an external (24-can) canister pack. To fill a canister in the pack, the fill line exit valve is closed, pressurizing the line. Then a canister valve is slowly opened while maintaining pressure at 5-10 psi. The valve is closed slightly if the pressure drops below the target range due to opening the canister too fast. The sample is filled slowly to 15-20 psi above ambient, and the canister valve is closed tight. Then the exit valve is reopened to resume the flushing flow.

Sample Canisters

Sample canisters are 2-L electropolished stainless steel are evacuated and sealed before sample missions. Lab analysis provides concentrations of more than 60 species, including CH4, CO, and many Non-Methane Hydro-Carbons (NMHC – hydrocarbons, halocarbons, alkylnitrates).